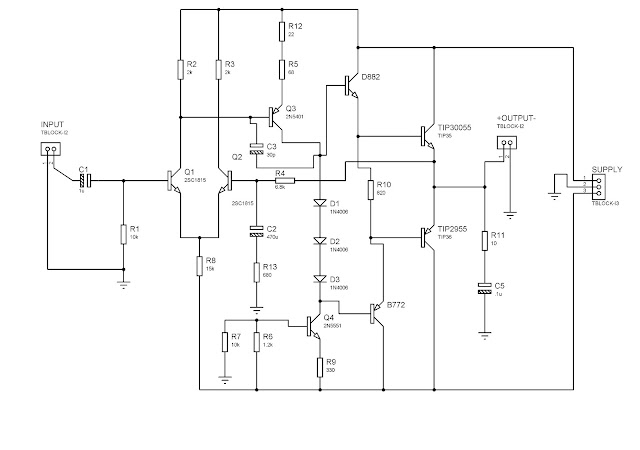

Shown below is the schematic diagram of the MOBOT:

Parts Used:

LM324 - operational amplifiers

L298 - H-Bridge (IC)

CNY70 - optocoupler sensors

PIC16f877a - microprocessor

Trimmer/potentiometer - adjustable resistor

LM7805 or LM323 or any regulators that has 3A rating and adjust the voltage to 5V.

(I suggest to use LM323 because it has a 3A current rating)

(I suggest to use LM323 because it has a 3A current rating)

resistors, capacitors

crystal oscillator- 20MHz

header pins

wires

RC Car

Program Code:

// HARDWARE:

// - PIC16F877A, 20MHz High Speed Oscillator

// - Oscillscope probe --> RC2/CCP1 (PWM1)

// - Oscillscope probe --> RC1/CCP2 (PWM2)

/*

*/

#include <pic.h>

#include "delay.h"

//SENSOR

//#define RIGHT RB0

//#define MIDDLE RB1

//#define LEFT RB2

#define RIGHT RB2

#define MIDDLE RB1

#define LEFT RB0

#define STOPPER RA2

//Configuration bits

__CONFIG(HS & WDTDIS & PWRTDIS & UNPROTECT & LVPDIS);

//Defines

#define normal 0b11000111 //PWM2 Duty Cycle = 90

#define slow 0b10101110 /*value here (PWM Duty Cycle = 80%)*/

#define slowest 0b10101110 /*value here (PWM Duty Cyle= 70%)*/

//Function Prototypes

void PWMInit(void);

unsigned int a=0;

void main()

{

TRISB = 0x0F;

TRISA = 0b00000100;

ADCON1 = 0x06;

PWMInit();

while(1)

{

if(RA2==1)

{

if(LEFT == 1 && MIDDLE == 0 && RIGHT == 1)

{

RA0 = 0;RA1 = 0;CCPR2L=normal;

}

else if(LEFT == 0 && MIDDLE == 0 && RIGHT == 1)

{

RA0 = 1;RA1 = 0;CCPR2L=slow;

}

else if(LEFT == 1 && MIDDLE == 0 && RIGHT == 0)

{

RA0 = 0;RA1 = 1;CCPR2L=slow;

}

else if(LEFT == 0 && MIDDLE == 1 && RIGHT == 1)

{

RA0 = 1;RA1 = 0;CCPR2L=slowest;

}

else if(LEFT == 1 && MIDDLE == 1 && RIGHT == 0)

{

RA0 = 0;RA1 = 1;CCPR2L=slowest;

}

}

else if(RA2==0)

{

CCPR2L=0;

}

}

}

/*----------------------------------------------------------------

PWM PROGRAMMING

----------------------------------------------------------------*/

//Initialize CCP1 & CCP2 for PWM Operation

void PWMInit(void)

{

TMR2 = 0x00; //Clear TMR2 & CPP related registers

T2CON = 0x00;

CCP1CON = 0x00;

CCP2CON = 0x00;

PR2 = 249; //Set PWM freq = 5Khz

CCPR2L = normal; //Set PWM2 Duty Cycle

TRISC1 = 0; //Enable PWM2 output pin

T2CKPS1 = 0; //Prescaler = 4

T2CKPS0 = 1;

CCP2CON = 0x0C; //CCP2 in PWM mode

TMR2ON = 1; //Enable TMR2. PWM signal is generated.

return;

}

For the micro-controller part, I used the PIC16F877A. I utilized this PIC due to the fact that I allocated its PWM pin in order to control the speed of my motor. It really takes time to have an accurate design and codes for this project. There are numerous ways to do this project and this is one of the easiest circuit I have seen. I actually used a CNY70 for the sensors. Based on the circuit given above, the sensor there is the CNY70. To determine the pins, be sure to have the mark point of the CNY70 on your right.

Here is the output of my MOBOT:

Note: The design is basically up to you on how creative you are. =)

MOBOT MADE BY:

KIRK BENEDICT P. MACARAEG