One of the requirements for the 1st semester in our Robotics subject is to create a robotic arm or either a gripper. Our group decided to create a robotic arm but we didn't have enough time and resources to create a robotic arm, instead we made a gripper/end-effector. Our gripper is controlled by a servo motor. The servo motor is driven by a 555 timer. We connected two tact-switch for the gripping functionality of the gripper.

So what is a servo motor and how was it controlled by the 555 timer?

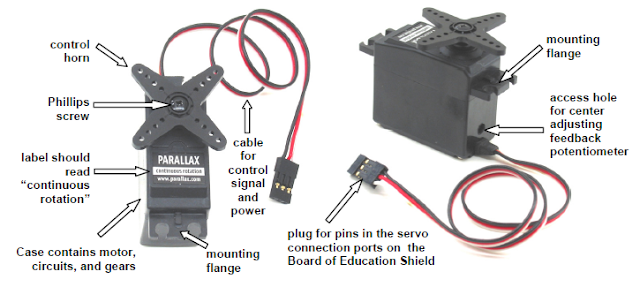

A Servo motor is a small device that incorporates a three wire DC motor, a gear train, a potentiometer, an integrated circuit, and an output shaft bearing. Of the three wires that stick out from the motor casing, one is for power, one is for ground, and one is a control input line. The shaft of the servo can be positioned to specific angular positions by sending a coded signal. As long as the coded signal exists on the input line, the servo will maintain the angular position of the shaft. If the coded signal changes, then the angular position of the shaft changes.

Here is an image of a servo-motor:

This is a special kind of motor, often used as the "muscles" of a robot. A servomotor takes a stream of pulses, where the width of each pulse controls the absolute position of the servo. This allows for precise positioning of motor turns. To do this, we're going to use a 555 timer in "Astable" mode - this will run it as an oscillator.

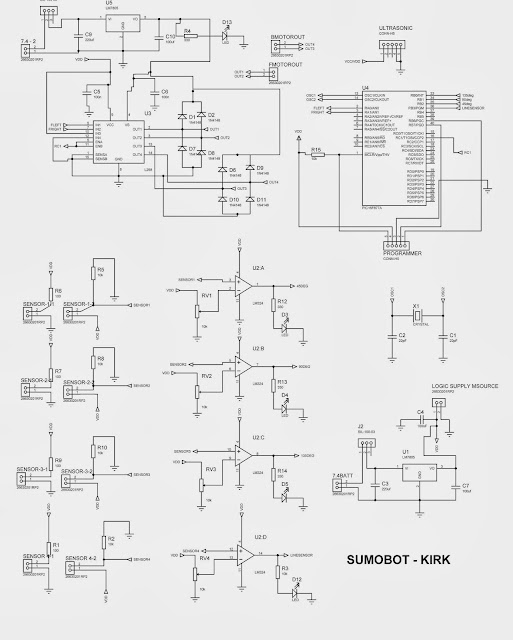

Here is the circuit diagram used for controlling the servo motor:

The two switches controls the rotation of the servo. The circuit is powered by a 7V DC source.

Here are some images of our Robotic Arm [Gripper]:

The output of our gripper was not well-designed due to limitation of resources and time. But at least we pulled out something like this. All of the parts from the gripper are recycled parts as well as the servo motor. The servo motor was found in a garbage can, believe it or not. LOL (-_~)

Here is a unit test video of our Gripper:

Project Made By:

Kirk Benedict P. Macaraeg

Jonald B. Sarmiento

Lindsey Baguio